King Ludwig Bread

King Ludwig Masterclass

Spelt – an extraordinary grain?

We reveal: Differences in taste from two different leavening processes:

Spelt sourdough vs. Crowning discipline, Detmold three-stage rye sourdough

Attention: Anyone who asks questions about spelt that have already been answered in the text will be publicly shamed! So: read first, then ask!

And if you think: They’re crazy! You’re right. Of course we want to overwhelm you, challenge you.

On the verge of afterwit:

Certain breads get the development names of:

Spelt blessing…

Spelt blessing I

Spelt blessing II

etc.

Because, thank goodness, they don’t contain any spelt.

Within the spelt eating crowd there is a particularly orthodox, proud contingent, over which you can see a halo on closer inspection. We learn: spelt is an extraordinary grain to which we dedicate ourselves today.

Biology:

Due to its stronger roots, spelt can absorb nitrogen better. It requires little or no nitrogen fertilization and therefore also thrives on poor soils, up to an altitude of over 1,000 meters. Spelt is a healthy grain and does not need as many pesticides. The protection of the strong husk covering the actual grain means there is no need for ear treatment. However, spelt has significantly lower yields than wheat or rye. Because of the husk, the coat that protects the grain from environmental influences, processing is time-consuming and tricky. That is why there are only a few genuine “original spelled varieties” in cultivation in Germany: Frankenkorn, Oberkulmer Rotkorn, Schwabenspelz, Schwabenkorn, Spelz, Holstenkorn, Ostro. Bauländer spelt is the basis for green spelt. It is grown in northern Baden-Württemberg and harvested when it is milk ripe. This is followed by kiln drying, historically over a beech wood fire, in which the spelt kernel becomes a slightly glassy and spicy aromatic green kernel, which, like a spice, can be used, for example, to flavor bread.

The spelt varieties cultivated in Germany are genetically closely related to one another, so that one cannot fall back on a multitude of characteristics in order to “circumvent” known weaknesses of spelt such as poor stability or the frequently occurring ear kink. Due to the close relationship to common wheat, the two types of grain can be crossed. The crossing of the Rouquin variety resulted in a wheat in the husk and spelt in the name. The hybrid, usually imported from Belgium and France, misleads the ignorant end user. Instead of an inexpensive spelt with the good baking properties of wheat, he ultimately just gets wheat. Especially since the typical spelt characteristics such as the nutty taste are lost through the crossing. Not least thanks to such experiments, we attach great importance to knowing our millers personally in order to be able to convince ourselves directly of the quality of our spelt. Incidentally, there are clear differences in taste among the closely related spelt varieties – and the following applies: the older the better. Prof. F. Longin, University of Hohenheim, has dealt in depth with this topic.

Milling

Spelt is stored with its husk in its raw form, which protects the grain and makes chemical treatments unnecessary, but increases the storage voume. Before milling, the spelt is de-husked and cleaned.

The peeled wholegrain spelt has a considerable germination capacity of over 95% and is the starting product for all other stages: flakes, groats, semolina, wholegrain meal, wholegrain and bolted flours.

The most common type of flours are 630, 812 and 1050.

The classic, long-term grinding process on roller mills gives the miller the best grinding result and good baking quality. Spelt should not be milled on rye mills, which are usually short and deep. Bakers that grind their own flour achieve good results on classic stone mills (results in flaky fine meal). Similar grinding results are also achieved with steel disk mills.

Zentrofan milling brings high oxidation effects, but also increases the mechanical stress on the starch grain. Extremely fine wholemeal flours with high water absorption are ground this way. However, the volume yield of the final baked goods is rather modest and the damage to the starch structures can lead to cleavage marks in the bottom area of the spelt bread. Zentrofan flours therefore are better for pastry baking

Flour treatment

In order to gain baking security, stability and time, ascorbic acid or acerola is added to the flour from time to time. Large mills (often manufacturers of ready-to-use spelt mixes) try to instill a wheat-like baking behavior in spelt with ascorbic acid. Without these baking agents, the spelt dough has to be kneaded more gently, held for a long time, and stretched in between. This is associated with considerable additional work, but it is this long dough process that supports the good tolerance of spelt and, in addition to enhancing the taste, also reduces the phytin levels. In order to get the best wholemeal flours in terms of baking technology, the grain layers should be left rather coarse. If the aleurone layer is finely ground, the properties of the gluten and starch can be affected. Light spelt flour has the best baking properties when core flour (endosperm) is added. That is why a quality miller never uses the full spelled flour yield. Storing the flour after grinding also increases its water absorption and helps loosen the crumb.

Spelt baking- Special features in working with spelt

The aids used by the modern baker (not necessarily a quality term) not only save time, but also save qualifications: In the bakery, the dough maker no longer has to be able to assess the perfect kneading point, the oven operator no longer has to be able to judge the status of the proof. By adding baking additives, a salable product always leaves the oven. Fortunately, the increasing interest in spelt has led to a return to the actual qualifications of the bakery trade. Craftsmanship is required to make bread with excellent taste from only flour, water, salt and possibly a little yeast.

Fermentation temperatures

With yeast-risen spelt baked goods, the dough temperature should not exceed 25 ° C (the dough temperature is not the same as the room temperature!). Significantly lower temperatures delay the development of the dough too much, significantly higher temperatures lead to breads that go stale quickly.

Kneading

Spelt doughs require patience and attention, but reward you with a special taste. They are extremely sensitive to over-kneading, which is why you should approach this with a lot of sense. The purists among the homebaking experts only mix the dough briefly and then lift it up repeatedly (stretching and folding). Once you have passed the critical point, the dough loses its stand, flows apart and it is no longer possible to shape the bread. Maybe you can then pull yourself out of the affair with a decent foccacia. Dough that is barely kneaded can be saved by storing it in a cool place and by regularly stretching and folding it.

Here, the concept of soaking is the key to success. If you bring water and flour together, the flour (starch & proteins) begins to swell and store water. This is supported by slow kneading. If you try to shorten this process with high energy and high speed, the dough structures are damaged from the outset and the delicate spelt dough can no longer be shaped into bread. The duration of the kneading process is directly dependent on the dough strength / hydration. So before you let the machine run endlessly with very soft dough, it is advisable to hold back 10 to 15% of the bulk water and only add it when the dough is almost fully kneaded. The window-pane test helps to assess the kneading process – if you stretch a piece of dough, a stable, evenly thin membrane should result. The optimal kneading of the dough also changes with the age of the flour. Therefore, one should always stick to it and watch while kneading. The optimally kneaded spelt dough behaves similarly to wheat dough: it detaches from the side of the bowl, gets a smooth, slightly lighter surface and pulls smaller bubbles.

Bread additives

In order to preserve the advantages of the spelt baked goods, no wheat-containing products should be included in the bread additives. Neither wheat flour as a filler nor wheat malt flour and wheat gluten are suitable additions. Barley malt flour or extract, some dextrose, acerola or ascorbin and possibly GMO-free enzymes are preferable.

Inclusion of fat

An addition of 1 to 2% fat makes the dough woolier, finer-pored and also adds a little more volume to the baked goods. Solid, unhydrogenated palm fats are best here.

Souring and Fermentation

The quality of spelt flour- or – wholegrain breads are improved by the addition of a spelt sourdough or fermented dough. The acidification ensures a more aromatic, rounder taste, better digestibility and freshness, natural protection against snags, better volume and better cutting ability. If you do not necessarily value 100% spelt, up to 10% of the total flour can be malted rye flour (rye malt scald). This gives a more harmonic sweetness and more moisture in the bread. The sourdough content should be about 10% and at the most 20% of the total flour amount. Such 100% spelt breads with natural acidification or fermentation bring out the fine aromas of spelt the best. A one-step acidification combined with the addition of 1% baker’s yeast makes baking much safer for less experienced bakers. In the case of mild acidification, lactic acid is formed in addition to the aroma component through natural yeast. Depending on the type of process, additional yeast can sometimes be dispensed with entirely. But even a combined process with a small amount of added baker’s yeast leads to good baking results.

Spelt pre-doughs

Spelt pre-doughs (TA 160) with 2% salt and up to 0.5% yeast, kept overnight and cooled, have proven to be good for rounding out the flavor and stabilizing the dough. However, they do not make any significant contribution to increasing the shelf-life of spelt breads.

Soakers and Scalds

Depending on the desired character of the spelt bread to be made, up to 30% of the total wholegrain flour, meal, or flakes can be prepared as a soaker or scald. Scalds or soakers should be prepared in a proportion of 1:1 grain to water and possibly 2% of the grain amount of salt. When scalding with 70°C hot water the soaking time is 2 to 2 hours. The soaker that is made with cool or warm water (approx. 30°C) should soak for 12 hours or more. The addition of salt can prevent extraneous fermentation. When considering effects on the shelf-life, scalds have the advantage of soakers.

Water-roux

The spelt water-roux is ideal for adding water to spelt dough. For this, up to approx. 5% of the total spelt flour is cooked in a ratio of 1: 4 with water and 2% salt to make a roux. The resulting paste can be stored in the refrigerator for several days in advance. However, the amount of spelt paste added must be tailored to the quality of the spelt and accordingly requires a little practice. The large amount of water bound in it must also be able to gelatinize during the baking process. If the bread is too moist, the crumb becomes too dense, the cut resistance suffers and the bread also tends to mold more quickly.

Cooked spelt

Whole spelt grains can also be boiled with water, in a ratio of 1: 3, with 2% salt per grain, for coarse-grained spelt breads with high moisture. The cooking process is similar to cooking rice. In a heat-resistant container with a lid, the soaked spelt kernels can be cooked in the oven for several hours with the residual heat of the oven from a residual heat of approx. 180 ° C. The cooked, cooled spelt grains replace up to 30% of the total meal or wholemeal flour content. A similar effect can be achieved with sprouted whole spelt grains. These are commercially available cooled and vacuum-packed. The germination process multiplies the vitamin content in the grain. The grains taste pleasantly malty-sweet to nutty and give the bread a grainy structure. The enzymes (proteases) activated during this process can break down gluten structures in the dough. This is avoided by not squeezing or grinding the sprouts, i.e. processing them whole if possible. It is not for nothing that such spelt sprout breads are widely enjoyed.

Plant fiber as dietary fiber and fresh keeper

Those who cannot or do not want to take so much time for soaking, cooking and scalding can achieve similar freshness effects by adding psyllium seed husk mixes. These natural dietary fibers are food and not an additive and absolutely tasteless. Another important advantage over the cooked and soaked additions is that all gluten is retained as a structural building material. So you get a significantly higher amount of water bound overall. The addition of 0.5 to 5% psyllium seed husk enables the hydration to be set from (TA) 180 to 200 – depending on the quality of the spelt. Spelt bread made in this way has a much longer shelf-life and is also richer in fiber. Here, too, it is important not to bind more water in the dough than can be gelatinized during the subsequent baking process.

Enriching with sugar and dextrose

Some large manufacturers of spelt baking mixes add sugar and dextrose to their ready mixes in quantities that run counter to our understanding of good bread.

This sweet / sour note tries to achieve greater taste appeal, especially among children. However, sugar is an acid generator and destroys precisely what makes good spelt – its good basic properties. This counteracts the easy digestibility of spelt. With a small addition of honey you get natural enzymes, inhibins and a light emulsifying effect in bread. In addition, a significantly more harmonious, complex aroma is created. Beet syrup is also suitable, some of which is fermented by the yeast. Sugar quantities above 5 to 7% have no place in a good wholemeal spelt bread.

Salt addition

The higher hydration (TA) of spelt loaves and rolls, and also softer wholegrain breads require a slightly higher amount of salt, otherwise the taste become quite bland. The salt content as a percent of flour is somewhere between 2.2-2.5%.

Summary

Spelt differentiates itself from wheat in many ways. For example, spelt flour absorbs significantly less water than wheat flour with the same dough strength. This is due, among other things, to the slightly different composition of gliadin and glutenin, the gluten proteins. If the dough is comparable, spelt tends to result in a dry bake more readily.

With the preceding statements, we have endeavored to present measures that can counteract this. A “crutch” alone, for example “just” a pre-dough or “only” a soaker, is usually not enough to completely compensate for this shortcoming. A combination of sensible measures, such as mild souring of the spelt with an added soaker or soured spelt in combination with a suitable amount of water-roux, always leads to optimum quality. Extrudates are also worth trying. Plant fibers in this area are very beneficial. Whether it is the psyllium seed husks with their beneficial bowel regulating properties, raw, cooked and grated potatoes or other stabilizers – in this way the entire gluten is retained and ensures much-appreciated stability. In the case of pastries and specialty rolls, which were traditionally made with spelt, the issue of water absorption takes care of itself. These doughs are extremely soft and require long processing, sometimes over night. Such dough processes require manual labor, there are no shortcuts. In terms of taste, we find spelt combined with rye to be superb. Both types of grain benefit from this combination, more than from combinations with other partners. That is the reason for our recipes today.

König Ludwig bread, which was still very common in bakeries years ago, is a protected trade secret ready-mix with the basic ingredients of spelt / rye in the bread. At least homemade sourdough can be used. And in-house water.

The combination of spelt and rye tames the sometimes intrusive taste of the spelt in an elegant way. Exellent combination!

Rationale: Why the comparison of two sourdough processes for the same recipe?

Because the Bread Brothers are of the opinion that the topic has never been examined and that it gives the bread gourmand a gold mine of knowledge with exactly this grain combination!

Conclusion

The addition of water, which is critical for spelt, is elegantly solved by a rye water-roux – rye hardly helps to ensure bread structure and bread volume, but binds large amounts of water in a roux. The entire spelt grain can 100

% be used. The rye flakes are pre-soaked using a scald and, with the appropriate scalding temperature , initiate the malting thanks to the enzymes present in the outer layers.

A recipe from the drawing board. Kudos, Dietmar.

Recipe No. 1

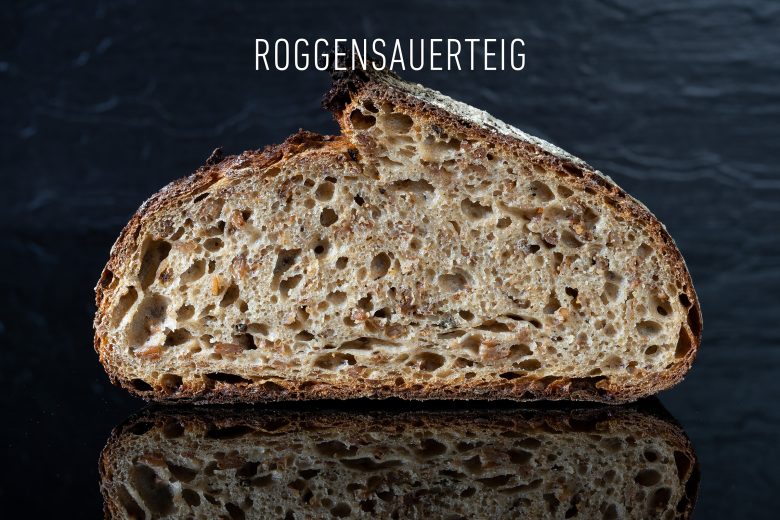

“3-Stage Rye Sourdough”

For a dough weight of 1994g / 3 pieces, each 665g of dough

Sourdough

The following sourdough table shows the individual sourdough steps. For the refresh sour, 1g of starter is used. The entire rye flour content is set in the sourdough.

| Stage | Flour | Water | Maturity Time | Hydration (TA) | C° |

| Refresh sour | 4g Rye flour (R/960) | 4g | 5-6 Hours | 200 | 27-29 |

| Foundation sour | 46g Rye flour (R/960) | 36g | 12 Hours | 180 | 24-26 |

| Full sour | 100g Rye 960 (R/960) 50g Rye 2500 (R/2500) | 220g | 4 Hours | 230 | 30-32°C |

Scald

| 200g | Rye flakes (20%) | 100% |

| 350g | Water 100°C | 175% |

| 5g | Salt | 2,5% |

Pour boiling water over the rye flakes and salt. Cover and allow to soak for 4-5 hours.

Water-roux

| 40g | Rye flour Type 960 | 100% |

| 160g | Water 35°C | 400% |

Stir the rye flour with water and then cook (approx. 90-95°C). Then cover and store in the refrigerator until ready to use.

Main dough

| 460g | Mature rye sourdough | 100% |

| 555g | Scald | 100% |

| 200g | Water-roux | 100% |

| 200g | Whole grain spelt flour | 20% |

| 360g | Spelt flour 630 | 36% |

| 20g | Salt | 2% |

| 10g | Liquid malt | 1% |

| 190g | Water | 34% |

Production:

- Mix all the pre-doughs and other ingredients slowly for 7-8 minutes. Then knead on a fast speed for half a minute.

- Place the dough in an oiled dough tub and stretch/fold once after 30 minutes.

- After a further dough development of 30 minutes (60 minutes total), divide the dough as you like and shape into round loaves. Then allow a 10 minute rest, once more shape into round loaves.

- Then form into elongated loaves and with the seam-side down place into floured proofing baskets.

- Final proof of about 50-60 minutes.

- Place in a preheated oven at 250°C with plenty of steam.

- Reduce the baking temperature to 210°C and bake until well browned.

Bread brothers’ verdict

The bread is rather dark – that’s important! The moist crumb in particular benefits from the toasted aromas, because diffusion processes can take place – this enables the fusion of crumb and crust aromas in the bread. We perceive malty-sweet roasted aromas, which are contrasted and underlined by the light, pleasant lactic acid of the 3-stage sourdough process. The loose crumb structure supports the tender, soft, elastic mouthfeel.

A revelation!

The high water content requires more salt to produce a well-rounded harmonic taste. (here: 2.5% salt as a perfecnt of flour)

Recipe No. 2

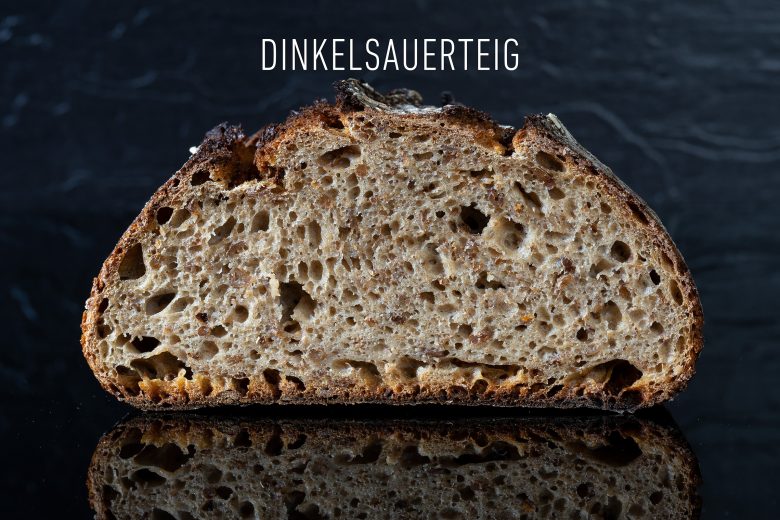

“Spelt sourdough” (with refreshed starter)

Spelt sourdough

| 200g | Spelt flour 630 | 100% |

| 200g | Water | 100% |

| 20g | Starter | 20% |

Dissolve the refreshed started completely in water and then mix with the spelt flour until lump-free. Maturity time 10-12 hours/ Sourdough temperature 25-27°C.

Scald

| 200g | Rye flakes (20%) | 100% |

| 350g | Water 100°C | 175% |

| 5g | Salt | 2,5% |

Pour boiling water over the rye flakes and salt. Cover and allow to soak for 4-5 hours.

Water-roux

| 40g | Rye flour Type 960 | 100% |

| 160g | Water 35°C | 400% |

Stir the rye flour with water and then cook (approx. 90-95°C). Then cover and store in the refrigerator until ready to use.

Main dough

| 420g | Maure spelt sourdough | 100% |

| 555g | Scald | 100% |

| 200g | Water-roux | 100% |

| 200g | Wholegrain spelt flour | 20% |

| 200g | Rye flour Type 960 | 20% |

| 160g | Spelt flour Type 630 | 16% |

| 20g | Salt | 2% |

| 10g | Liquid malt | 1% |

| 250g | Water | 45% |

Production:

- Mix all the pre-doughs and other ingredients slowly for 7-8 minutes. Then knead on a fast speed for half a minute.

- Place the dough in an oiled dough tub and stretch/fold once after 30 minutes.

- After a further dough development of 30 minutes (60 minutes total), divide the dough as you like and shape into round loaves. Then allow a 10 minute rest, once more shape into round loaves.

- Then form into elongated loaves and with the seam-side down place into floured proofing baskets.

- Final proof of about 50-60 minutes.

- Place in a preheated oven at 250°C with plenty of steam.

- Reduce the baking temperature to 210°C and bake until well browned.

Bread brothers’ verdict

Spelt lovers will have something to swallow with the result. The bread in itself is good, consistent. The bite is shorter, the crumb firmer, denser.

The complexity in taste and aroma does not match its brother’s. If we are looking for an advantage it is easier to spread butter on the slices. The malty-sweetness is also present here, the roast aromas are not present in the crumb though, they are much less pronounced.