Chocolate Croissant

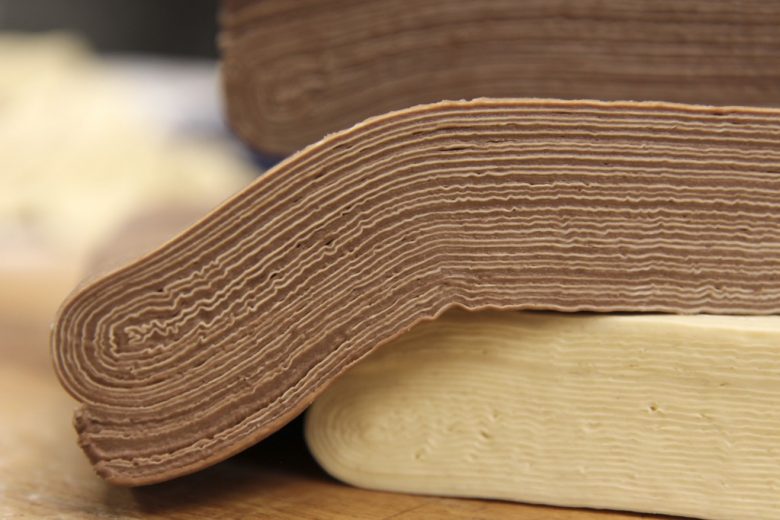

So what does the butter in the dough do that make croissants and Danish pastries so flaky? Butter is made up of fat and water. If you heat the butter, the water evaporates. The resulting steam lifts the dough and gives the pastry its flaky texture.

In order for the steam to work optimally, the butter must be worked evenly into the dough in fine layers. When the butter layers melt, the expanding steam drives the wafer-thin layers of dough apart and thus forms the well-known puff pastry texture.

The main difficulty in making laminated dough is spreading the butter evenly throughout the dough while making sure that it forms thin layers. For flaky pastries, it is important that the butter is processed cold, but the right technique is just as important.

Dough Production

Base dough “mixed”:

If the “mixed” variant is used, the amount of flour must be reduced by 10% compared to the kneaded dough. This reduced amount of flour is due to the short mixing phase during which the dough does not soften. To ensure even distribution and optimal dough development, it is important to dissolve the ingredients in water beforehand.

Production:

- 4-5 minute mixing time (mix the dough into a loose dough structure)

- Advantage: Through the lamination the loose dough structure turns into an elastic dough.

Base dough “fully mixed”

All the ingredients are kneaded into a well mixed, plastic dough.

Production:

- Mix the dough for 5-6 minutes and then knead for approx. 5-6 minutes. The longer the dough is kneaded, the more gluten develops (with longer kneading times the dough should become weaker).

- Disadvantage: With this process there is a risk that the dough structure will be short and tough when laminating. This can result in a small volume in the final product.

After making the dough, it is rolled into a square and then stored at -15°C for 60 minutes. (Dough relaxes and is better for the dough-butter consistency).

Laminating

Laminating creates an alternating layer of dough and butter. These layers are there for the subsequent leavening, so that the baked goods get a flaky and airy structure. The higher the butter content in the dough, the more layers of fat the dough needs.

Wrapping:

In order to get even butter layers, the consistency of the butter needs to be the same as the base dough. Butter that is too firm breaks and butter that is too soft is pressed out or absorbs into the dough during lamination.

Laminating:

Only even and careful rolling / laminating will bring good and even results. The number of laminations depends on the amount of butter that is used. Most laminated yeast doughs are given three simple laminations.

- 10-20% Butter content / 3 simple laminations = 27 fat layers

- 20-30% Butter content / 3 simple laminations = 27 fat layers

- 25-45% Butter content / 1 doubled + 2 simple laminations = 36 fat layers

Video Instructions:

Storing:

Laminated yeast dough can be stored for 1-2 weeks at -18°C until ready to use. If necessary, let the dough thaw for 18-20 hours at 3-4°C the day before. Prepare and bake the dough individually.

Choco-Croissant Recipe

For a dough weight of 795g dough + 200g Butter = 14 Choco-Croissants

Pre-dough:

- 15g Lievito Madre

- 45g Wheat flour Type 700

- 15g Water 30°C

- 5g Milk 30°C

- 10g Yolk

- 6g Brown sugar

- 5g Butter

Mix the ingredients for 6-7 minutes on at a slow speed and then cover and allow to mature at room temperature for 12-15 hours (Since only half a yolk is required in the pre-dough, the remaining yolk can be weighed with the milk for the main dough and stored in the refrigerator until further processing!).

Main dough:

- 101g Mature pre-dough

- 450g Wheat flour Type 700

- 25g Cocoa

- 210g Milk

- 20g Yolk

- 60g Brown sugar

- 15g Butter

- 10g Salt

- 8g Yeast

- 6g Honey

- + 14 Chocolate bars (to wrap inside when forming)

Mixing time: 6 minutes slow & 4 minutes fast DT: 20-24°C Maturity time: 90 minutes

Instructions:

- After kneading the dough is rolled into a rectangle, wrapped in plastic and stored at -18°C for 90 minutes.

- In the meantime, shape the butter into a 5-7mm thick butter-brick and the store at 4°C until ready to use.

- After the base dough has cooled, the butter is wrapped inside. After wrapping, the dough is worked through 3 simple laminations. In order to ensure even butter layers, the dough must be given a 30 minute rest at -18°C between each lamination phase.

- After the last lamination, the dough is stored at – 18°C for 2 hours and then at 4°C until ready to continue.

- After the relaxation phase the dough is rolled out. Each piece of dough should be about 7cm wide x 16 cm long (the whole dough sheet therefore should be 49cm wide and 32cm long= 14 Croissant).

- Before rolling up, each dough piece can be topped with a chocolate bar. When rolling up, make sure as little flour as possible is rolled into the dough. Too much dusting flour causes cavities to form during baking = the croissants collapse on themselves.

- After shaping, cover the croissants with plastic and let them proof.

- Once they have at least doubled in volume they are brushed with egg and sprinkled with brown sugar.

- The Croissants are baked at 200°C with light steaming. After a 5 minutes initial baking phase, turn the oven down to 170°C. After half of the baking time you can switch to convection heat, this helps the Croissants maintain their shape after baking.

- Baking time of about 18-20 minutes (oven door should only be opened at the end of the baking time!!).